Silicon nitride formula powder

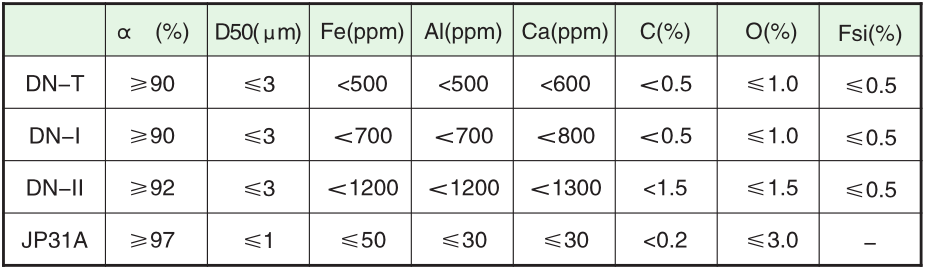

Our company uses different grades of polycrystalline silicon powder as raw materials to directly nitrify and dry process refinement of DN series ceramic grade α-silicon nitride powder. It has high alpha ratio, low impurity content, high degree of crystallization, small particle size (size Can be customized), with excellent molding characteristics and good sintering characteristics, to provide high cost-effective raw materials for the ceramic industry. For customers in the ceramic industry pursuing high performance, our company also provides the JP31A α-silicon nitride powder prepared by the ammonolysis process, which has ultra-low impurity content, high α ratio and extremely high sintering activity. It is a high-end ceramic product. Preferred raw materials.

(1) Manufacturing structural devices: such as balls and rollers of rolling bearings, sliding bearings, sleeves, valves used in industries such as metallurgy, chemical industry, machinery, aviation, aerospace and energy, and structures with requirements for wear resistance, high temperature resistance and corrosion resistance Devices, nozzles for rockets, nozzles for missiles;

(2) Surface treatment of metals and other materials: such as molds, cutting tools, turbine blades, turbine rotors, and cylinder inner wall coatings;

(3) Composite materials: such as metal, ceramic and graphite-based composite materials, rubber, plastics, paints, adhesives and other polymer-based composite materials;

(4) Wear-resistant self-lubricating nanoparticle film, used for surface protection of mobile phones, high-end automobiles, etc., wear-resistant coatings, electrophoretic paint additives, play a high wear-resistant characteristics.